Physical Vapor Deposition (PVD) by means of evaporation has continued to be the leading technology for optical thin film coatings. However, as optical filter coatings for medical, defense and commercial applications become tighter a shift in favor of sputter deposition technology with optical monitoring will continue, though the former will always maintain a crucial role in the process.

Additionally, optical components continue to find their way into semiconductor applications to meet an ever-growing consumer demand for increased speed. A clear example is the integration of optical components on semiconductor chips, which has given rise to a new generic name: Photronics.

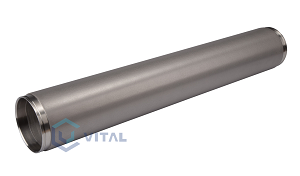

VTFM is a uniquely positioned supplier of PVD evaporation and sputter materials. Raw materials largely originate from in-house reclamation, also referred to as ‘urbanmining’. Adding further value Vital’s ability to maintain control of material characteristics (purity, grain size, homogeneity, etc.) critical to the PVD process stems from in-house refining, melting, casting, forging, rolling and bonding capabilities.

The aforementioned production resources are equally complimented by an R&D team available to assist customers with process improvements, including new material compositions and geometries or depositing layer stacks within our own applications laboratory.

CN

CN EN

EN